联系我们

- 电话:025-8658 3475

- 传真:025-8658 3457

- 邮箱:info@fire-test.com

- 网址:www.cprce.com

- 地址:中国江苏省南京市江东中路118号德盈大厦16F

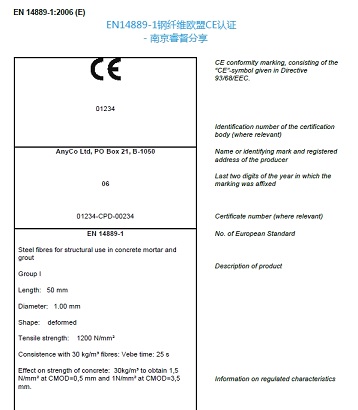

出口欧盟钢纤维CE认证 EN14889-1(欧盟NB公告号发证)

来源:线缆CPR认证服务平台 浏览:967次 发布于:2024-3-18

1. 标准名称—EN 14889-1(钢纤维CE认证、混凝土钢纤维CE认证)

EN 14889-1:2006—Fibers for concrete-Part 1: Steel fibers-Definitions, specification and conformity.

EN 14889-1:2006—混凝土用纤维,第1部分: 钢纤维的定义、性能及一致性。

钢纤维包括波浪型钢纤维,平直型钢纤维,端钩型等等,更多关于混凝土纤维欧盟CE认证,请参考睿督官网 http://www.hksmartps.com/ce/steelfibres

2. 出口欧盟钢纤维CE认证强制时间

2007年1月1日起,所有在欧盟市场销售的钢纤维产品都必须经过CE认证,其产品加贴CE标识,才能在市场范围内销售。钢纤维产品CE认证根据EN 14889-1:2006标准进行认证。

3. 钢纤维欧盟CE认证产品认证法规及体系

钢纤维CE认证根据欧盟CPR建筑产品法规-No.305/2011/EU-CPR,根据EN 14889-1协调标准采用体系1或者体系3进行测试认证。钢纤维CE认证具体请联系南京睿督公司。钢纤维(混凝土纤维)制品CE认证必须由欧盟委员会认可的具备相关资质能力的指定公告机构(Notified Body)。

从2013年7月1日起,建筑产品CPR法规(Construction Product Regulation No.305/2011/EU-CPR法规)将全面取代原来的建筑产品CPD指令(Construction Product Directive简称89/106/EEC-CPD指令),欧盟CPR法规将对CE认证要求更加严格。

4. 出口欧盟钢纤维CE认证检测项目

a. Length: 长度

b. Diameter: 直径

c. Aspect ratio: 长径比

d. Tensile strength: 抗拉强度(EN 10002-1)

e. Modulus of elasticity: 弹性模量(EN 10002-1)

f. FPC 工厂审核

5. 钢纤维欧盟相关测试标准

EN 14889-1:2006—Fibers for concrete-Part 1: Steel fibers-Definitions, specification and conformity.EN 14889-1:2006—混凝土用纤维,第1部分: 钢纤维的定义、性能及一致性。

EN 14889-2:2006—Fibers for concrete-Part2:Polymer fibers-Definitions, specifications and conformity.

EN 14889-2:2006—混凝土用钢纤维——2:聚合物纤维的定义、性能和一致性。

南京睿督为欧盟公告号NB1301及NB1020等授权合作实验室,专业从事欧盟建筑产品CE认证十多年,在建材CE认证及CPR法规方面拥有丰富经验,咨询电话:025-8658 3475。

南京睿督公司咨询电话:025-8658 3475 400-603-6575

网址:www.hksmartps.com www.cprce.com

邮箱:info@hksmartps.com

微信:firetesting 或 17714189018

……

钢纤维混凝土小知识

Fiber-reinforced concrete (FRC) is concrete that has fibrous materials mixed in to increase the concrete’s durability and structural integrity. FRC has small, short, and discreet fibers that are randomly oriented yet uniformly distributed throughout the concrete. The fibers can be circular or flat and often make up one to three percent of the concrete mix’s total volume. Common fibers used in reinforced concrete include steel, glass, synthetic, and natural fibers.

纤维增强混凝土(FRC) 是混合了纤维材料以提高混凝土耐久性和结构完整性的混凝土。FRC 具有小而短且隐蔽的纤维,这些纤维取向随机但均匀分布在整个混凝土中。纤维可以是圆形的,也可以是扁平的,通常占混凝土混合物总体积的百分之一到百分之三。钢筋混凝土中常用的纤维包括钢、玻璃、合成纤维和天然纤维。

Why fibres are used? 为什么要使用纤维?

On its own, concrete lacks tensile strength and is prone to cracking. But fiber-reinforced concrete can improve tensile strength and control cracking in concrete structures that are often caused by plastic shrinkage and drying shrinkage. Fibers in concrete can also reduce the permeability of concrete, which limits the amount of water that bleeds out, further reducing shrinkage cracking during curing.

就其本身而言,混凝土缺乏抗拉强度,容易开裂。但纤维增强混凝土可以提高混凝土结构的抗拉强度并控制通常由塑性收缩和干燥收缩引起的开裂。混凝土中的纤维还可以降低混凝土的渗透性,从而限制渗出的水量,进一步减少养护过程中的收缩开裂。

The necessity of Fiber Reinforced Concrete纤维增强混凝土的必要性

1- It increases the tensile strength of the concrete.

1-它增加了混凝土的抗拉强度。

2- It reduces the air voids and water voids the inherent porosity of gel.

2-它减少了空气空隙,水空隙凝胶固有的孔隙率。

3- It increases the durability of the concrete.

3-它增加了混凝土的耐久性。

4- Fibers such as graphite and glass have excellent resistance to creep, while the same is not true for most resins. Therefore, the orientation and volume of fibers have a significant influence on the creep performance of rebars/tendons.

4-石墨和玻璃等纤维具有出色的抗蠕变性,而大多数树脂则不然。因此,纤维的取向和体积对钢筋/钢筋的蠕变性能有显著影响。

5- Reinforced concrete itself is a composite material, where the reinforcement acts as the strengthening fiber and the concrete as the matrix. It is therefore imperative that the behavior under thermal stresses for the two materials be similar so that the differential deformations of concrete and the reinforcement are minimized.

5-钢筋混凝土本身是一种复合材料,其中钢筋充当增强纤维,混凝土作为基体。因此,两种材料在热应力下的行为必须相似,以便将混凝土和钢筋的差异变形降至最低。

6- It has been recognized that the addition of small, closely spaced, and uniformly dispersed fibers to concrete would act as a crack arrester and would substantially improve its static and dynamic properties.

6- 人们已经认识到,在混凝土中添加小的、紧密间隔的、均匀分散的纤维将起到防裂剂的作用,并将大大改善其静态和动态性能。

Types of Fibers 纤维的种类

1- Steel fibers 1-钢纤维

2- Glass fibers 2-玻璃纤维

3- Carbon Fibers 3-碳纤维

4- Cellulose Fibers 4-纤维素纤维

5- Synthetic Fibers 5-合成纤维

6- Natural Fibers 6-天然纤维

Advantages Of Fibre Reinforced Concrete

纤维增强混凝土的优点

1-High modulus of elasticity for effective long-term reinforcement, even in the hardened concrete. Does not rust nor corrode and requires no minimum cover.

1-高弹性模量,即使在硬化混凝土中也能实现有效的长期加固。不会生锈或腐蚀,并且不需要最低限度的覆盖。

2-Ideal aspect ratio (i.e. the relationship between Fiber diameter and length) which makes them excellent for early-age performance.

2-理想的纵横比(即纤维直径和长度之间的关系),这使得它们在早期表现方面表现出色。

3-Easily placed, Cast, Sprayed and less labor-intensive than placing rebar.

3-易于放置,铸造,喷涂,并且比放置钢筋更省力。

4-Greater retained toughness in conventional concrete mixes.

4-在传统混凝土混合物中保留韧性更高。

5-Higher flexural strength, depending on the addition rate.

5-更高的抗弯强度,取决于添加率。

6-Can be made into thin sheets or irregular shapes.

6-可制成薄片或不规则形状。

7-FRC possesses enough plasticity to go under large deformation once the peak load has been reached.

7-FRC具有足够的塑性,一旦达到峰值载荷,就会发生较大的变形。8- Increased durability and high flexural rigidity.8-增加耐用性和高弯曲刚度。

9-Reduced permeability, bleeding, and formation of microcracks.

9-降低渗透性、渗色和微裂纹的形成。

10-Minimum weathering effect.

10-最小的风化效应。

11-Reduces deflection.

11-减少偏转。

12-Minimum corrosion.

12-最小的腐蚀。

南京睿督为欧盟公告号NB1301及NB1020等授权合作实验室,专业从事欧盟建筑产品CE认证十多年,在建材CE认证及CPR法规方面拥有丰富经验,咨询电话:025-8658 3475。

南京睿督公司咨询电话:025-8658 3475 400-603-6575

网址:www.hksmartps.com www.cprce.com

邮箱:info@hksmartps.com

……

苏公网安备 32010502010104

苏公网安备 32010502010104 官方微信

官方微信